Ineempawu ezikhethekileyo zomzimba nezekhemikhali, i-kaolin sisixhobo seminerali esiyimfuneko kwiseramikhi, ukwenziwa kwamaphepha, irabha, iiplastiki, iziqhoboshi, ukucokisa i-petroleum kunye namanye amacandelo obugcisa boshishino nezolimo nokhuselo lwesizwe. Ubumhlophe be-kaolin luphawu olubalulekileyo lwexabiso lesicelo.

Izinto ezichaphazela ubumhlophe be-kaolin

I-Kaolin luhlobo lodongwe olucolekileyo okanye ilitye lodongwe ikakhulu liqulunqwe ngeeminerali ze-kaolinite. I-crystal formula yekhemikhali yi-2SiO2 · Al2O3 · 2H2O. Inani elincinci leeminerali ezingezizo zodongwe ziyi-quartz, i-feldspar, i-iron minerals, i-titanium, i-aluminium hydroxide kunye ne-oxides, i-organic matter, njl.

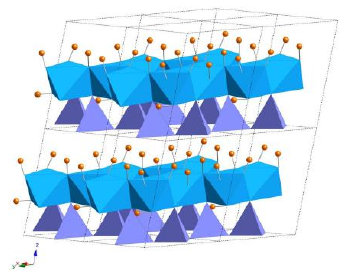

Ubume beCrystalline yekaolin

Ngokwemeko kunye nobume bokungcola kwi-kaolin, ukungcola okubangela ukuhla kobumhlophe be-kaolin kunokwahlulwa ngokwamacandelo amathathu: i-organic carbon; Izinto zePigment, ezifana neFe, Ti, V, Cr, Cu, Mn, njl. Amaminerali amnyama, afana ne-biotite, i-chlorite, njl. Ngokuqhelekileyo, umxholo we-V, i-Cr, i-Cu, i-Mn kunye nezinye izinto kwi-kaolin zincinci, ezinomphumo omncinci kumhlophe. Ukwakhiwa kwamaminerali kunye nomxholo wentsimbi kunye ne-titanium zizinto eziphambili ezichaphazela ubumhlophe be-kaolin. Ubukho babo abuyi kuchaphazela kuphela ubumhlophe bendalo be-kaolin, kodwa buchaphazela ubumhlophe bayo be-calcined. Ngokukodwa, ubukho be-iron oxide bunempembelelo embi kumbala wodongwe kwaye kunciphisa ukukhanya kwayo kunye nokumelana nomlilo. Kwaye nokuba isixa se-oxide, i-hydroxide kunye ne-hydrated oxide ye-iron oxide yi-0.4%, kwanele ukunika intlenga yodongwe ebomvu ukuya kumbala otyheli. Ezi oksidi zentsimbi kunye hydroxides ingaba hematite (obomvu), maghemite (red-brown), goethite (brown yellow), limonite (orenji), hydrated iron oxide (brownish obomvu), njl Kunokuthiwa ukuba ukususwa ukungcola intsimbi kwi-kaolin idlala indima ebaluleke kakhulu ekusetyenzisweni ngcono kwe-kaolin.

Imeko yokwenzeka kwentsimbi

Imeko yokwenzeka kwentsimbi kwi-kaolin yeyona nto iphambili emisela indlela yokususa intsimbi. Inani elikhulu lezifundo zikholelwa ukuba i-crystalline iron ngendlela yamasuntswana amahle ixutywe kwi-kaolin, ngelixa i-amorphous iron ifakwe kumphezulu wamasuntswana amahle e-kaolin. Okwangoku, imeko yentsimbi kwi-kaolin yahlulwe yaba ziindidi ezimbini ekhaya nakwamanye amazwe: enye ikwi-kaolinite kunye ne-accessory minerals (efana ne-mica, i-titanium dioxide kunye ne-illite), ebizwa ngokuba yintsimbi yesakhiwo; Enye ikwimo yeeminerali zentsimbi ezizimeleyo, ezibizwa ngokuba yintsimbi yasimahla (kubandakanywa nentsimbi engaphezulu, i-fine-grained crystalline iron kunye ne-amorphous iron).

Intsimbi esuswe ngokususwa kwentsimbi kunye nomhlophe we-kaolin yintsimbi yamahhala, ngokukodwa ibandakanya i-magnetite, i-hematite, i-limonite, i-siderite, i-pyrite, i-ilmenite, i-jarosite kunye nezinye iiminerali; Uninzi lwentsimbi lukhona ngendlela ye-limonite ye-colloidal ehlakazekileyo, kunye nexabiso elincinci ngendlela ye-spherical, acicular and irregular goethite kunye ne-hematite.

Ukususwa kwentsimbi kunye nendlela yokwenza mhlophe ye-kaolin

Ukwahlula kwamanzi

Le ndlela isetyenziswa ikakhulu ukususa iiminerali ezitshabalalisayo ezifana nequartz, feldspar kunye ne mica, kunye nokungcola okurhabaxa okufana nenkunkuma yamatye, kunye neeminerali zentsimbi kunye netitanium. Izimbiwa ezingacocekanga ezinoxinano olufanayo kunye nokunyibilika kwi-kaolin azinakususwa, kwaye ukuphuculwa kobumhlophe akubonakali ngokucacileyo, nto leyo ifanele ukuxhamla kunye nokwenza mhlophe komgangatho ophezulu we-kaolin ore.

Ukwahlukana kwamagnetic

Ubumdaka bezimbiwa zentsimbi kwikaolin budla ngokuba yimagnethi ebuthathaka. Okwangoku, indlela yokwahlula imagnethi ephezulu isetyenziswa ikakhulu, okanye iiminerali ezinozibuthe ezibuthathaka ziguqulwa zibe yintsimbi eyomeleleyo ye-iron oxide emva kokugcadwa, zize emva koko zisuswe ngendlela eqhelekileyo yokwahlula imagnethi.

Umsesane othe nkqo umahluli wemagnethi ephezulu

Isahluli semagnethi enethambeka ephezulu yodaka lwe-electromagnetic

Iqondo lobushushu eliphantsi le-superconducting isahlukanisi kazibuthe

Indlela yokudada

Indlela ye-flotation isetyenziswe ukunyanga i-kaolin ukusuka kwiidiphozithi eziphambili kunye nesekondari. Kwinkqubo ye-flotation, i-kaolinite kunye ne-mica particles ziyahlukana, kwaye iimveliso ezihlambulukileyo zizinto ezininzi ezifanelekileyo zomgangatho woshishino. Ukwahlula okukhethiweyo kwe-flotation ye-kaolinite kunye ne-feldspar ngokuqhelekileyo kuqhutyelwa kwi-slurry ene-pH elawulwayo.

Indlela yokunciphisa

Indlela yokunciphisa kukusebenzisa i-agent yokunciphisa ukunciphisa ukungcola kwentsimbi (okufana ne-hematite kunye ne-limonite) kwi-trivalent state ye-kaolin ukuya kwi-ion ye-iron bivalent enyibilikayo, esuswa ngokuhluzwa kunye nokuhlamba. Ukususwa kokungcola kwe-Fe3 + kwi-kaolin ye-industrial ngokuqhelekileyo kufezekiswa ngokudibanisa iteknoloji yomzimba (ukuhlukana kwamagnetic, i-flocculation ekhethiweyo) kunye nokunyangwa kweekhemikhali phantsi kweemeko ze-acidic okanye zokunciphisa.

I-Sodium hydrosulfite (Na2S2O4), ekwabizwa ngokuba yi-sodium hydrosulfite, iyasebenza ekunciphiseni nasekukhupheni intsimbi esuka kwi-kaolin, kwaye ngoku isetyenziswa kushishino lwe-kaolin. Nangona kunjalo, le ndlela kufuneka iqhutywe phantsi kweemeko ezinamandla ze-acidic (pH <3), okubangelwa iindleko eziphezulu zokusebenza kunye nefuthe lokusingqongileyo. Ukongeza, iipropathi zeekhemikhali ze-sodium hydrosulfite azizinzile, zifuna ukugcinwa okukhethekileyo kunye nokubiza kunye namalungiselelo okuthutha.

I-Thiourea dioxide: (NH2) 2CSO2, TD) yi-arhente yokunciphisa eyomeleleyo, enenzuzo yokunciphisa amandla, ubuhlobo bendalo, izinga eliphantsi lokubola, ukhuseleko kunye neendleko eziphantsi zokuvelisa ibhetshi. I-Fe3 enganyibilikiyo+ kwi-kaolin inokuncitshiswa ibe yi-Fe2+ enyibilikayo ngokusebenzisa i-TD.

Emva koko, ubumhlophe be-kaolin bunokwandiswa emva kokuhluzwa kunye nokuhlamba. I-TD izinzile kakhulu kwindawo yokushisa kunye neemeko ezingathathi hlangothi. Ubuchule bokunciphisa obunamandla be-TD bunokufumaneka kuphela phantsi kweemeko ze-alkalinity enamandla (pH> 10) okanye ukufudumeza (T> 70 ° C), okubangelwa iindleko eziphezulu zokusebenza kunye nobunzima.

Indlela ye-oxidation

Unyango lwe-oxidation lubandakanya ukusetyenziswa kwe-ozone, i-hydrogen peroxide, i-potassium permanganate kunye ne-sodium hypochlorite ukususa i-carbon adsorbed layer ukuze kuphuculwe ubumhlophe. I-kaolin kwindawo enzulu phantsi komthwalo onzima kakhulu ingwevu, kwaye i-iron kwi-kaolin ikwimeko yokunciphisa. Sebenzisa ii-oxidizing agents eziqinileyo ezifana ne-ozone okanye i-sodium hypochlorite ukuze i-oxidize i-FeS2 engaxutywanga kwi-pyrite kwi-soluble Fe2 +, kwaye emva koko uhlambe ukususa i-Fe2 + kwinkqubo.

Indlela yokucoca i-asidi

Indlela yokucoca i-asidi kukuguqula ukungcola kwentsimbi enganyibilikiyo kwi-kaolin kwizinto ezinyibilikayo kwizisombululo ze-acidic (i-hydrochloric acid, i-sulfuric acid, i-oxalic acid, njl.), ngaloo ndlela iqonda ukuhlukana kwi-kaolin. Xa kuthelekiswa namanye ama-asidi e-organic, i-asidi ye-oxalic ithathwa njengeyona nto ithembisayo ngenxa yamandla ayo e-asidi, ipropati enhle yokudibanisa kunye nokukwazi ukunciphisa okuphezulu. Nge-asidi ye-oxalic, isinyithi esinyibilikisiweyo sinokugqithiswa kwisisombululo se-leaching ngendlela ye-oxalate ene-ferrous, kwaye inokuqhutyelwa phambili ukwenza i-hematite ecocekileyo ngokusebenzisa i-calcination. I-asidi ye-oxalic inokufumaneka ngexabiso eliphantsi kwezinye iinkqubo zoshishino, kwaye kwinqanaba lokudubula lokwenziwa kwe-ceramic, nayiphi na i-oxalate eseleyo kwizinto eziphathwayo iya kuchithwa kwi-carbon dioxide. Abaphandi abaninzi baye bafunda iziphumo zokunyibilikisa i-iron oxide nge-oxalic acid.

Indlela yokubala ubushushu obuphezulu

Ukubala yinkqubo yokuvelisa iimveliso zekaolin zodidi olukhethekileyo. Ngokweqondo lokushisa lonyango, amanqanaba amabini ahlukeneyo e-kaolin e-calcined aveliswa. Ukubala kuluhlu lwamaqondo obushushu angama-650-700 ℃ kususa iqela le-hydroxyl yesakhiwo, kwaye umphunga wamanzi ophumayo uphucula ukuqina kunye nokungafihli kwe-kaolin, uphawu olufanelekileyo lwesicelo sokugquma ngephepha. Ukongeza, ngokufudumeza i-kaolin kwi-1000-1050 ℃, ayinako ukunyusa kuphela ukubola, kodwa inokufumana ubumhlophe be-92-95%.

I-Chlorination calcination

Intsimbi kunye ne-titanium zasuswa kwiiminerali zodongwe, ngakumbi i-kaolin nge-chlorination, kwaye iziphumo ezilungileyo zafunyanwa. Kwinkqubo ye-chlorination kunye ne-calcination, kwiqondo lokushisa eliphezulu (700 ℃ - 1000 ℃), i-kaolinite iye yafumana i-dehydroxylation ukuze yenze i-metakaolinite, kwaye kwiqondo lokushisa eliphezulu, izigaba ze-spinel kunye ne-mullite zenziwe. Olu tshintsho lwandisa i-hydrophobicity, ubulukhuni kunye nobukhulu bamasuntswana ngokusebenzisa i-sintering. Iiminerali eziphathwa ngolu hlobo zinokusetyenziswa kumashishini amaninzi, njengephepha, i-PVC, irabha, iiplastiki, izinto zokuncamathelisa, ukupolisha kunye nentlama yamazinyo. I-hydrophobicity ephezulu yenza ezi zimbiwa zihambelane ngakumbi neenkqubo ze-organic.

Indlela yeMicrobiological

Itekhnoloji yokucoca iMicrobial yezimbiwa sisifundo esitsha sokusetyenzwa kwezimbiwa, kubandakanywa ubuchwepheshe bemicrobial leaching technology kunye nemicrobial flotation technology. Ubuchwephesha be-microbial leaching of minerals bubuchwephesha bokutsalwa obusebenzisa intsebenziswano enzulu phakathi kwemicroorganisms kunye neeminerali ukutshabalalisa icrystal lattice yezimbiwa kunye nokunyibilikisa amacandelo aluncedo. I-pyrite ene-oxidized kunye nezinye i-sulfide ores eziqulethwe kwi-kaolin zinokucocwa ngeteknoloji ye-microbial extraction. Iimicroorganisms ezisetyenziswa ngokuqhelekileyo ziquka i-Thiobacillus ferrooxidans kunye ne-Fe-reducing bacteria. Indlela ye-microbiological inexabiso eliphantsi kunye nongcoliseko oluphantsi lokusingqongileyo, olungayi kuchaphazela iimpawu ezibonakalayo kunye neekhemikhali ze-kaolin. Yindlela entsha yokucoca kunye nokwenza mhlophe okulindelweyo kuphuhliso lwezimbiwa ze-kaolin.

Isishwankathelo

Ukususwa kwentsimbi kunye nonyango olumhlophe lwe-kaolin kufuneka lukhethe eyona ndlela ilungileyo ngokwezizathu zombala ezahlukeneyo kunye neenjongo ezahlukeneyo zesicelo, ukuphucula ukusebenza okumhlophe okubanzi kweeminerali ze-kaolin, kwaye yenze ukuba ibe nexabiso eliphezulu lokusetyenziswa kunye nexabiso lezoqoqosho. Indlela yophuhliso yexesha elizayo kufuneka ibe kukudibanisa iimpawu zendlela yekhemikhali, indlela yomzimba kunye nendlela ye-microbiological organically, ukwenzela ukuba badlale ngokupheleleyo kwiinzuzo zabo kwaye bathintele izinto ezingeloncedo kunye neziphene zabo, ukuze bafezekise umphumo ongcono wokuba mhlophe. Kwangaxeshanye, kukwayimfuneko ukuqhubela phambili ukufunda indlela entsha yeendlela ezahlukeneyo zokususa ukungcola kunye nokuphucula inkqubo yokwenza ukususwa kwentsimbi kunye nokumhlophe kwe-kaolin kuphuhlise kwicala lekhabhoni eluhlaza, esebenzayo kunye nephantsi.

Ixesha lokuposa: Mar-02-2023