QHUBEKA OMNYE UXINEZELEKO ELIPHEZULU LOKUSILA ROLL

Umda wosetyenziso

I-single-drive high high-high-high rolling roll yenzelwe ngokukhethekileyo ukucola iintsimbi zesamente kwangaphambili, inkunkuma yezimbiwa, iintsimbi ezikrwada njalo njalo zibe ziigranule ezincinci, ukutyumza iiminerali zesinyithi (ore iron, ores manganese, copper ores). , i-lead-zinc ores, i-vanadium ores kunye nezinye) kunye nokusila iiminerali ezingezizo ezesinyithi (i-gangues yamalahle,

feldspar, nephe-line, dolomite, limestone, quartz, njalo njalo) ibe ngumgubo.

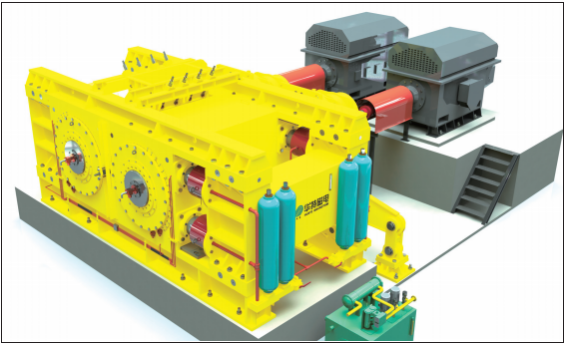

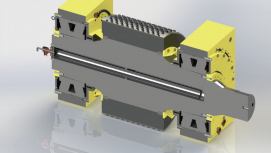

Ulwakhiwo kunye noMgaqo wokuSebenza

◆Umzobo woMgaqo wokuSebenza

I-singledrive yoxinzelelo oluphezulu lokusila roll ithatha

umgaqo wokusila we-aggregate extrusion.

Omnye ngumqulu omileyo kwaye omnye ngumqulu oshenxisekayo.

Imiqulu emibini ijikeleza ngokuchaseneyo ngesantya esifanayo.

Izixhobo zingena kwindawo ephezulu yokutya,

kwaye zigaywe ngenxa ye-extrusion ngoxinzelelo oluphezulu kwisithuba semiqulu emibini, kwaye ikhutshwe phantsi.

◆Qhuba inxalenye

Inye kuphela imoto efunekayo,

amandla ahanjiswa ukusuka kumqulu omileyo ukuya kumqulu oshukumayo ngenkqubo yegiya,

ukuze imiqulu emibini idityaniswe ngokupheleleyo kungabikho friction .

Umsebenzi wonke usetyenziselwa ukukhutshwa kwezinto eziphathekayo,

kwaye izinga lokusetyenziswa kwamandla liphezulu, eligcina i-45% yombane xa kuthelekiswa noluhlu oluqhelekileyo lokusila uxinzelelo oluphezulu .

◆Inkqubo yokufaka uxinzelelo

I-spring mechanical pressure edibeneyo yokusetyenziswa kwenkqubo yenza ukuba umqulu oshukumayo uphephe ukuguquguquka .

Xa kukho intsimbi yangaphandle ingena.

inkqubo yokusetyenziswa koxinzelelo lwentwasahlobo ibeka umva ngokuthe ngqo kwaye iphendule kwangexesha, iqinisekisa ukuba izinga lokusebenza liphezulu ukuya kuma-95%;

Ngelixa umqulu wesiqhelo wokusila woxinzelelo oluphezulu wenza ukuba kuthintelwe, ioyile yehydraulic kufuneka ikhutshwe ngombhobho wokuthomalalisa uxinzelelo.

Isenzo sibambezelekile, esinokubangela umonakalo kwi-roll surface okanye ukungasebenzi kakuhle kwe-hydraulic system .

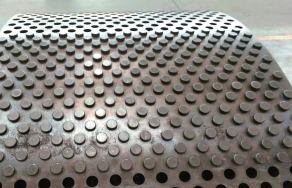

◆Rola umphezulu

Umphezulu we-roll ujongene ne-welded kunye ne-alloy wear-resistant welding material, kwaye ukuqina kunokufikelela kwi-HRC58-65; uxinzelelo luhlengahlengiswa ngokuzenzekelayo kunye nezinto,

engaphumeleli kuphela injongo yokugaya, kodwa ikhusela i-roll roll;

umqulu oshukumayo kunye nomqulu omileyo usebenza ngolungelelwano ngaphandle kokutyibilika.

Ngoko ke, ubomi benkonzo ye-roll surface buphezulu kakhulu kunobuxhakaxhaka obuqhelekileyo bokugaya umqulu .

Iimpawu eziphambili zobuGcisa

◆ Ukusebenza ngokuGqibeleleyo. Xa kuthelekiswa nezixhobo zemveli zokutyumza, amandla okusebenza akhula ngo-40 - 50%.

Umthamo wokucubungula wePGM1040 unokufikelela malunga ne-50 - 100 t / h, kunye namandla angama-90kw kuphela.

◆ Ukusetyenziswa kwamandla aphantsi . Ngokwendlela enye yokuqhuba, idinga injini enye kuphela ukuyiqhuba.

Ukusetyenziswa kwamandla kuphantsi kakhulu. Xa kuthelekiswa ne-HPGR yokuqhuba kabini, inokunciphisa ukusetyenziswa kwamandla nge-20 ~ 30%.

◆ UmGangatho oNgcono wokuNxibelela . Ngokuqhuba kwemoto enye kuphela, ukusebenza kongqamaniso lwemiqulu emibini kuhle kakhulu.

Ngeendawo ze-welding zokunxiba, ii-rolls zinomgangatho olungileyo wokunxiba kwaye zinokugcinwa ngokulula.

◆ Izinga eliphezulu lokuSebenza: ≥ 95%. Ngoyilo lwesayensi, izixhobo zinokucinezelwa liqela lentwasahlobo yoxinzelelo oluphezulu.

Uxinzelelo olusebenzayo lunokulungelelaniswa ngokuzenzekelayo njenge-compress yeqela lasentwasahlobo. Akukho ndawo yokungasebenzi kakuhle .

◆ I-Automation ephezulu kunye nohlengahlengiso olulula. Ngaphandle kwenkqubo ye-hydraulic, kukho izinga eliphantsi lokungasebenzi

◆ Umphezulu oqengqelekayo udityaniswe nge-alloy engagungqiyo, enobunzima obuphezulu kunye nokungagugi kakuhle;

Uxinzelelo oluya entwasahlobo luvela kumandla okusabela kwezinto, kwaye uxinzelelo luhlala lulinganisa,

engaphumeleli nje injongo yokutyumza,

kodwa ikwakhusela umphezulu wokuqengqeleka; umqulu oshukumayo kunye nomqulu omileyo zithungelwe kwaye ziqhutywa yinkqubo yegiya,

kwaye isantya silungelelaniswe ngokupheleleyo, ngaloo ndlela sinqanda ukukhuhlana kokutyibilika phakathi kwezinto kunye nomphezulu wokuqengqeleka.

Ngoko ke, ubomi benkonzo buphezulu kakhulu kunobo be-double drive HPGR.

◆ Ubume obuqinileyo kunye nendawo encinci yomgangatho.

Iiparamitha zobuGcisa

| Umzekelo | Roll idamamithamm | Rollububanzimm | M ax .feedsize(Isamente, islagi sentsimbi, i-oreslag) mm | Esona sondloubukhulu(yentsimbindiya l e ,non-metaliminerali) mm | mmUbungakanani bemveliso(isamente)mm | Amandla okuqhubaT/h | M o t oamandla Kw | Imilinganiselo yolwandlalo(L×W×H)mm |

| PGM0850 | φ800 | 500 | 50 | 30 | Ukuhlela<4 | 30~40 | 37 | 2760×2465×1362 |

| PGM1040 | φ1000 | 400 | 50 | 30 | Ukuhlela<4 | 50~80 | 90 | 4685×4300×2020 |

| PGM1060 | φ1000 | 600 | 50 | 30 | Ukuhlela<4 | 70~110 | 110 | 4685×4300×2020 |

| PGM1065 | φ1000 | 650 | 50 | 30 | ukuthoba<4 | 100~160 | 200 | 5560×4500×2200 |

| PGM1250 | φ1200 | 500 | 50 | 30 | Ukuhlela<4 | 120~180 | 250 | 6485×4700×2485 |

| PGM1465 | φ1400 | 650 | 50 | 30 | Ukuhlela<4 | 240~320 | 630 | 9200×6320×3600 |

| PGM1610 | φ1600 | 1000 | 50 | 30 | Ukuhlela<4 | 500~650 | 1250 | 10800×8100×4400 |

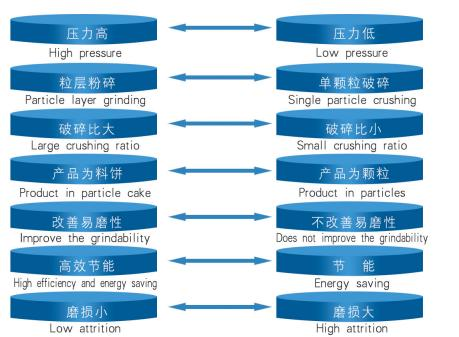

UKUTHWELELWA PHAKATHI KWE-HPGR ENYE I-DRIVE NE-CONVENTIONAL HPGR

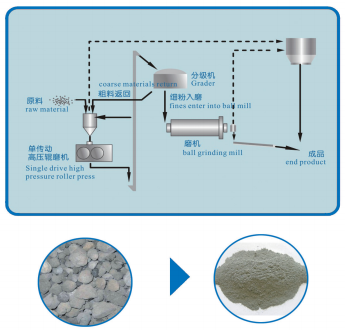

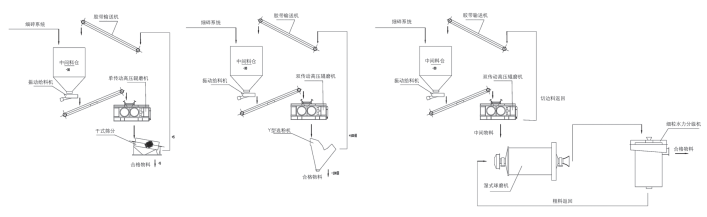

INKQUBO YAPHAMBILI YOKUSILA ITSHATHI YOQEQESHO YE-HPGR ENYE

Ukugaya kwangaphambili kwesamente, i-ore slag kunye ne-steel slag "Ukutyunyuzwa okungaphezulu kunye nokunciphisa okuncinci, ukubuyisela ukugaya ngokutyumza", oko kukuthi, ukugaya kwangaphambili, kuye kwaba yiteknoloji eqhelekileyo yenkqubo yokuvelisa umbhobho wokunyusa imveliso kunye nokunciphisa ukusetyenziswa kwamandla. . Njengezona zixhobo ziphezulu zokugaya kwangaphambili zokugcina amandla, i-HPGR ye-single-drive inokutyumza izixhobo ukuya kwi-4mm okanye -0 .5mm, apho i-0 .08mm ibala ngaphezu kwe-30%. Umthamo we-mill yebhola esetyenzisiweyo unokunyuswa nge-50 ~ 100%, kwaye inkqubo yokugaya ukusetyenziswa kwamandla ingancitshiswa nge-15 ~ 30%.

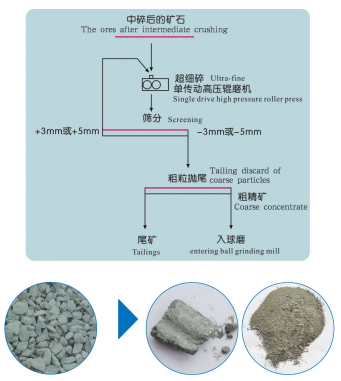

I-ULTRA FINE INKQUBO YOKUTSHATYA ITSHATE YOMQULO YEMINERAL EMETALI ENE-Drive ENGE HPGR

I-Ultra Fine Crushing of Metallic Mineral

Xa iiminerali zidlula i-gap phakathi kwee-rolls ezimbini, zichithwa zibe ngamaqhekeza amancinci -5 mm okanye -3 mm kunye nomthamo omkhulu wepowder ngamandla oxinzelelo oluphezulu . Ngenxa yobuthathaka bokubambisana kwamandla okudibanisa phakathi kwe-mineral esebenzayo kunye ne-ganggue, ukukhathala ukuphuka okanye i-micro-crack kunye noxinzelelo lwangaphakathi lwenziwa lula. Inxalenye yojongano iya kwahlulwa ngokupheleleyo .

Ngenxa yomxholo ophezulu womgubo ocolekileyo okhutshiweyo kwi-HPGR kunye nenyaniso yokuba iiminerali zityunyuzwa ecaleni kwendawo yokuqhawula, xa kuthelekiswa nokutyunyuzwa okuqhelekileyo, umlinganiselo wokuhluma kwiimveliso ezityumziweyo uyancitshiswa, kwaye umsila ulahlwe ukusebenza- i-fect ilungile.

Zombini ibakala elirhabaxa lokugxila kunye nesivuno sokulahla inkunkuma ziphuculwe kakhulu .

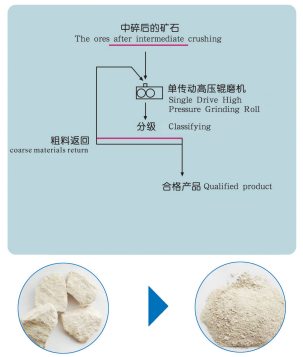

INKQUBO YOKUFAKA IZICELO ITSHATHI YOLAWULO YENKQUBO ENGEYIMETALI ENE-HPGR ENYE.

Non-Metallic Mineral UkuSila

Xa kuthelekiswa nezixhobo zokusila zemveli, i-HPGR ene-single-drive inoncedo lomthamo omkhulu womatshini omnye, ukusetyenziswa kwamandla aphantsi, ukuguga okuncinci kunye nongcoliseko lwentsimbi; i-fineness yemveliso inokulawulwa ukusuka kwi-20 mesh ukuya kwi-120 mesh, enokuthi ithathe indawo yebhola yebhola kwaye idale inkqubo entsha yokugaya .

HPGM SERIES UXINZELELO ELIPHEZULU LOKUSILA ROLL

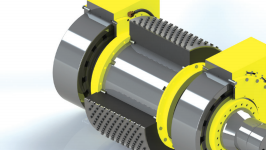

Umgaqo wokuSebenza

I-HPGM series yoxinzelelo oluphezulu lokusila umqulu luhlobo olutsha lwezixhobo zokusila ezonga amandla eziyilwe ngumgaqo we-high-pressure material layer pulverization. Iqulathe imiqulu emibini ecudisayo ejikeleza ngokuhambelanayo ngesantya esiphantsi. Enye ingumqulu omileyo kwaye enye ingumqulu oshukumayo, zombini ziqhutywa yinjini enamandla amakhulu. Izinto eziphathekayo zondliwa ngokulinganayo ukusuka ngasentla kwemiqulu emibini, kwaye ziqhutyelwa ngokuqhubekayo kwi-gap ye-roll nge-squeezing roll. Emva kokuba uphantsi koxinzelelo oluphezulu lwe-50-300 MPa, ikhekhe lezinto ezixineneyo zikhutshwa kumatshini . Kwikhekhe lezinto ezikhutshweyo, ukongeza kumlinganiselo othile weemveliso eziqeqeshiweyo, isakhiwo sangaphakathi samasuntswana eemveliso ezingenazo iziqinisekiso zizaliswe ngenani elikhulu leentanda ezincinci ngenxa yoxinzelelo oluphezulu, ukwenzela ukuba amandla okugaya izinto. iphuculwe kakhulu. Kwizinto eziphathekayo emva kwe-extrusion, emva kokuqhawula, ukuhlula kunye nokuhlolwa, izinto ezintle ezingaphantsi kwe-0.8 mm zingafikelela malunga ne-30%, kwaye izinto ezingaphantsi kwe-5 mm zinokufikelela ngaphezu kwe-80%. Ke ngoko, kwinkqubo eyongezelelweyo yokusila, ukusetyenziswa kwamandla okusila kunokuncitshiswa kakhulu, ukuze amandla okuvelisa izixhobo zokusila asetyenziswe ngokupheleleyo, ngokubanzi umthamo wenkqubo yokugaya ibhola unokunyuswa ngama-20% ~ 50. I-%, kwaye ukusetyenziswa kwamandla apheleleyo kungancitshiswa nge-30% ~ 50% okanye ngaphezulu.

Iinkalo zeSicelo

Zininzi iintlobo zemithombo yentsimbi ekrwada e-China, kodwa iimpawu zeentlobo ezininzi zeeminerali zimbi, ziyahlukahlukana kwaye zilungile. Ukuze kusonjululwe iingxaki ezibalaseleyo kuqoqosho, ubugcisa kunye nokukhuselwa kokusingqongileyo kuphuhliso lwemigodi, amashishini emigodi yesinyithi asekhaya azisa, asetyise kwaye afunxe izixhobo ezitsha nezisebenzayo zokuvelisa imigodi. Kule mvelaphi yemarike, i-HPGR sisixhobo sokusila esisebenza kakuhle kuqala kwaye saboniswa, kwaye siqala ukusetyenziswa kumashishini emigodi yesinyithi yasekhaya. Ikwasesona sixhobo sokuvelisa umgodi sixhalabele kakhulu ishishini lemigodi yasekhaya . Kunokuthiwa i-HPGR isetyenziswa kakhulu kwimigodi yesinyithi yasekhaya . I-HPGR isetyenziswe ngokubanzi ekhaya nakwamanye amazwe ekusileni kwishishini lesamente, igranulation kushishino lweekhemikhali, kunye nokusila kakuhle kwepellet ukwandisa indawo ethile yomhlaba. Isetyenziselwa ukutyunyuzwa kwentsimbi yentsimbi ukufezekisa iinjongo ezahlukeneyo ezifana nokwenza lula inkqubo yokutyumza, ukutyumza ngakumbi kunye nokuncincika, ukuphucula imveliso yenkqubo, ukuphucula isiphumo sokusila okanye izikhombisi zokwahlula.

Umda wosetyenziso olusebenzayo

1. Ukugaya okuphakathi, okulungileyo kunye ne-ultrafine yezinto ezininzi .

2. Kwi-industry processing industry, inokubekwa phambi kwebhola lebhola, njengesixhobo sokugaya kwangaphambili, okanye wenze inkqubo yokugaya edibeneyo kunye nebhola lebhola.

3. Kwishishini le-pellet ene-oxidized, inokutshintsha indawo yokusila esetyenziswa ngokuqhelekileyo yokufuma.

4.Kwizinto zokwakha, izinto eziphikisayo kunye namanye amashishini, zisetyenziswe ngempumelelo kwi-cement clinker, i-limestone, i-bauxite kunye nezinye izinto zokugaya.

Izinto eziluncedo kwimveliso

1. Uyilo loxinzelelo oluqhubekayo luqinisekisa uxinzelelo olugudileyo phakathi kwemiqulu kwaye luqinisekisa umphumo wokutyumza.

2. Ukulungiswa kokuphambuka ngokuzenzekelayo, kunokukhawuleza ukulungelelanisa i-gap roll ukuqinisekisa ukugudiswa kwezixhobo.

3. Inkqubo yokuhlukana komda inciphisa umphumo weempembelelo ezinqamlekileyo kwisiphumo sokutyumza.

4. Ngezikhonkwane ze-carbide ezine-cemented, ubomi benkonzo ende, ukugcinwa lula, kunye nokutshintshwa.

5. Ibhanki yevalvu ithatha amacandelo angaphandle, kwaye inkqubo ye-hydraulic inoyilo olufanelekileyo kunye nokuthembeka okulungileyo.

Ubume beHPGR

| Umzekelo | Roll idamamithamm | Roll ububanzi mm | Umsebenziumthamo | Ubungakanani bokutya | Ubunzima bomatshinit | Amandla afakiweyo |

| HPGM0630 | 600 | 300 | 25-40 | 10-30 | 6 | 74 |

| HPGM0850 | 800 | 500 | 50-110 | 20-35 | 25 | 150-220 |

| HPGM1050 | 1000 | 500 | 90-200 | 20-35 | 52 | 260-400 |

| HPGM1250 | 1200 | 500 | 170-300 | 20-35 | 75 | 500-640 |

| HPGM1260 | 1200 | 600 | 200-400 | 20-35 | 78 | 600-800 |

| HPGM1450 | 1400 | 500 | 200-400 | 30-40 | 168 | 600-800 |

| HPGM1480 | 1400 | 800 | 270-630 | 30-40 | 172 | 800-1260 |

| HPGM16100 | 1600 | 1000 | 470-1000 | 30-50 | 220 | 1400-2000 |

| HPGM16120 | 1600 | 1200 | 570-1120 | 30-50 | 230 | 1600-2240 |

| HPGM16140 | 1600 | 1400 | 700-1250 | 30-50 | 240 | 2000-2500 |

| HPGM18100 | 1800 | 1000 | 540-1120 | 30-60 | 225 | 1600-2240 |

| HPGM18160 | 1800 | 1600 | 840-1600 | 30-60 | 320 | 2500-3200 |

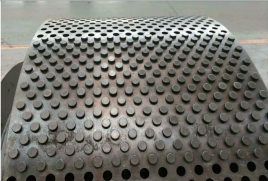

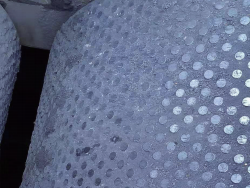

Uhlobo olutsha lwetekhnoloji yomphezulu we-stud roll

Yamkela i-alloy studs ezikumgangatho ophezulu ezinobunzima obuphezulu kunye nokumelana nokunxiba kakuhle.

Ulungiselelo lwe-stud luyilwe ngokulinganisa ikhompyuter,

kwaye ulungelelwaniso lunengqiqo, olunokwenza umaleko wezinto ezifanayo phakathi kwee-studs, ukukhusela ngokufanelekileyo i-studs kunye ne-roll surface,

kunye nokuphucula ubomi bobugqwetha benkonzo yokucudisa umqulu . I-studs ifakwe kunye ne-adhesives ekhethekileyo evela kumazwe angaphandle ukuze kube lula ukutshintshwa.

Itekhnoloji yokwahlulahlula i-roll bushing kunye ne-main shaft

Umzimba oyintloko we-squeezing roll yenziwe ngentsimbi ekhuniweyo ephezulu, kwaye i-roll bushing yenziwe nge-high-quality alloy steel . I-shaft ephambili kunye nemiqulu yenziwe ngezinto ezahlukeneyo, eziphucula ukuqina kwe-shaft ephambili kunye nokuqina kwe-roll bushing. Ubomi benkonzo ye-shaft bushing buphuculwe kakhulu. Ukutshintshwa kwe-roll bushing kukulungele.

Ukuthwala itekhnoloji yokunyuswa ngokukhawuleza kunye nokwehliswa kweebheringi zomngxunya okumgangatho ophezulu wamkelwe kwaye itanki yeoli yoxinzelelo oluphezulu yenziwe kwangaphambili. Ukuthwala kunokwehliswa ngokulula ngempompo yeoli yoxinzelelo oluphezulu, ukunciphisa kakhulu ubunzima bokutshintsha indawo yokuthwala kunye nokuphucula ukusebenza kakuhle

Itekhnoloji yokutywina edibeneyo emininzi

Isitywina sokutywinwa samkela iintlobo ezahlukeneyo ze-J kunye nohlobo lwe-V kunye ne-labyrinth seals, kwaye iteknoloji yokutywina edibeneyo iqinisekisa ngokufanelekileyo umphumo wokutywinwa kwe-bearing.

Intsimbi ekrwada yokuNceda ukuhamba

Umphezulu oPhezulu wokuNxitywa oNganyanzeliyo uMphezulu onezikhonkwane

Emva kokuba izixhobo zikhutshiwe,

i-dense material layer yenziwa kwi-roll surface ukukhusela i-roll surface.

Impahla engekasilwa

Ikhekhe leMathiriyeli