Ngenxa yokwembiwa kwemithombo yesinyithi yesinyithi kwilizwe lam, imithombo yayo enyiniweyo iya inqabile. Ke ngoko, iimfuno zezixhobo zokusetyenzwa kwezimbiwa ziya ziphezulu nangaphezulu, ngakumbi ukusetyenziswa okubanzi kweentsalela zezimbiwa kuhambelana ngokuthe ngqo nokuzingisa kobutyebi belizwe lam. Umbuzo yindlela yokuphumeza imigaqo-nkqubo yogcino lwamandla, ukunciphisa ukusetyenziswa, kunye nokunciphisa ukukhutshwa okucetywayo ngurhulumente, ukugcina ukusetyenziswa kwexesha elide lobutyebi, kunye nokwandisa ixabiso lemithombo ibe ngumba obalulekileyo ojongene noshishino lwemigodi.

Okwangoku, isikhululo seenqwelomoya sokubuyisela umsila esisetyenzisiweyo kulwahlulo lwemagnethi lwentsimbi yentsimbi kwilizwe lam lumalunga ne-1600Gs, kwaye kunzima ukubuyisela iiminerali ezibuthathaka kwimagnethi. Ngesi sizathu, kukho imfuneko engxamisekileyo yokuphuhlisa isixhobo esiluncedo esinamandla aphakamileyo entsimi kwaye esikwaziyo ukunciphisa isiqulatho sentsimbi kwiintsalela zezimbiwa ukwandisa ukusetyenziswa kwangoku kwezimbiwa kwilizwe lam.

I-Shandong Huate Magnetoelectric Technology Co., Ltd. iye yazibophelela kuphando lwezixhobo zokubuyisela ukwahlukana kwemagnetite yokwahlukana kwemagnethi ukususela ngo-2005. Okwangoku, inani elikhulu le-ferrites ziveliswa njengoomatshini bokubuyisela i-tailings magnetic, kwaye ezintathu zechungechunge zenziwe. Iimveliso ezineenkcukacha ezininzi ziye zaba zizixhobo eziphambili zokubuyisela i-tailings. Ukuze unyuse ngakumbi izinga lokubuyisela intsimbi yezixhobo zokubuyisela iintsalela zezimbiwa, emva kophando olucokisekileyo, umboniso kunye novavanyo lokuhlalutya, ukusetyenziswa kwe-neodymium iron boron imathiriyeli kunye nendlela yokothula kwindawo engeyiyo eyemagnetic iye yaphucula ngakumbi izinga lokubuyisela intsimbi. , kwaye ukukhulula kulula, okunokuhlangabezana neemfuno zokusetyenziswa.

Ulwakhiwo kunye nomgaqo-siseko wokusebenza we-middle-field yamandla e-semi-magnetic yokuzikhulula umatshini wokubuyisela umsila

Umatshini wokubuyisela umsila wokulahla umbindi we-semi-magnetic usebenzisa i-neodymium iron boron njengesixhobo semagnethi. Indawo yokwahlula inommandla wemagnethi ophakathi kunye nendawo enemagnethi ebuthathaka. Iipali kazibuthe ngokutshintshanayo zenza isixokelelwano sesangqa sesangqa semagnethi. Isingxobo esijikelezayo sinikezelwa ngaphandle kwenkqubo yemagnethi. , Inkqubo yamagnetic igxininiswe, inxalenye yegobolondo igxininiswe kwi-pulp, kwaye iinqununu zamagnetic kwi-pulp ziqhubeka zixutywa yindlela yokujikeleza okuqhubekayo. Amasuntswana amagnetic aqhubeka nokuwa kunye nokujikeleza kwe-casing, ukwenzela ukuba izinto ezingezizo zemagneti kwizinto zombane zisoloko zihlanjwa. Indawo ephezulu ngasekunene yesiqingatha sonyaka wemagnethi ayinayo imagnethi. Xa izinto zamagnetic zingena kwindawo engeyiyo i-magnetic, phantsi kwesenzo samanzi okuhlamba kunye nobunzima bezinto eziphathekayo, Khulula izinto eziphathekayo kwi-tank concentrate.

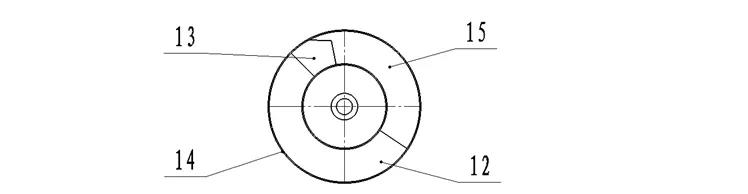

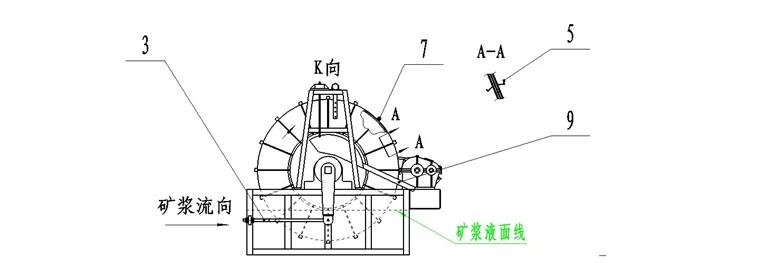

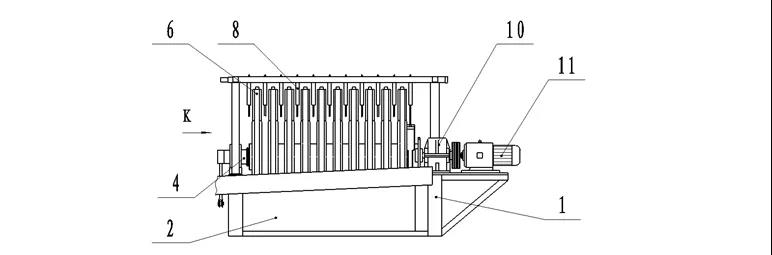

I-mid-field yamandla e-semi-magnetic self-unloading tailings recovery machine luhlobo lwe-disc-uhlobo oludityanisiweyo, kwaye inani leediski zemagneti linokumiselwa ngokweemfuno zomthamo wokucubungula. Ukwakhiwa kwayo kuboniswe kwi-Figure 1, 2, kunye ne-3. I-1- isakhelo; I-2- itanki ye-slurry; I-3-i-disk adjustment mechanism; 4- i-shaft ephakathi; 5- isiphambukisi; I-6-ukuqokelela itreyi; 7- ibhloko ephazamisayo; 8- umbhobho wokugungxula; 9- ukubamba i-chute; I-10 -Umnciphisi; 11-motor; I-12-indawo enamandla yamagnetic; I-13-ebuthakathaka indawo yamagnetic; I-14-fixed disk; I-15-non-magnetic indawo.

Isakhelo senziwe ngentsimbi edibeneyo kwaye isetyenziselwa ikakhulu ukuxhasa i-shaft ephakathi, ukufaka inkqubo yokuhambisa kunye nokufaka itanki ye-slurry.

I-disc yamagnetic iyisakhiwo se-semi-magnetic, kwaye i-disc yokuqokelela evaliweyo ifakwe ngaphandle, i-magnetic conductive plate ifakwe phakathi kwe-double-layer magnetic steel, kwaye inxalenye engezantsi ye-disc yokuqokelela ifakwe kwi-tank ye-slurry 2.

I-disc magnetic inikezelwa ngentsimi yamagnetic ephakathi, intsimi yamagnetic engenamandla kunye nommandla ongeyena-magnetic, kwaye igxininiswe kwi-axis ephakathi.

Iziphelo ezibini zepani yokuqokelela zibonelelwa ngobuninzi beepleyiti zesikhokelo ezisasazwe kwi-ray shape, kunye nobuninzi beebhloko ezishukumisayo ezisasazwa ngokulinganayo zibonelelwa kumda ongaphandle.

Okwangoku, ezinye ii-concentrators kwilizwe lam zisebenzisa oomatshini bokubuyisela i-disk tailings, kodwa ngenxa yempembelelo embi ye-desliming, imathiriyeli yamagnetic iya kutsala umva xa izinto zemagneti zingena kwindawo engeyiyo-magnetic ukusuka kwindawo enemagnethi ephakathi, kwaye idiski kunye ne-scraper zinxiba ngokukhawuleza. , Ngokuxhomekeke kwizithintelo ezithile ezisetyenziswayo.

Ngokujonga le meko ingentla, inkampani yethu ithatha i-middle-field-strength semi-annular disk ene-neodymium-iron-boron etywinwe ngokupheleleyo isakhiwo esiza kulungiswa kwi-axis ephakathi, kwaye i-axis ephakathi igxininiswe ngaphandle kokujikeleza. I-pan yokuqokelela ejikelezayo, inxalenye engezantsi ye-pan yokuqokelela ifakwe kwi-slurry flow trough ukuze ifunxe izinto eziphathekayo. Imoto kunye nesinciphisi zisetyenziselwa ukuqhuba itreyi yokuqokelela ukuze ijikeleze, kwaye i-adsorbed imaterial yamagnetic idlula kumhlaba wemagnethi ophakathi kunye nemagnethi ebuthathaka, ize ikhuphe emva kokufikelela kwindawo engeyiyo-magnetic, esombulula ezi ngxaki zingasentla.

I-chute ye-material icwangciswe phakathi kwepani nganye yokuqokelela, kunye ne-magnetic material kwi-pan yokuqokelela iyahlanjwa kwaye iphume ngaphandle kunye ne-chute yezinto eziphathekayo.

Inkqubo yokudluliselwa iqulethwe yimoto yokuguqula i-frequency, i-reducer, i-coupling, i-sleeve yokuhambisa, njl. Ezi ndawo zikhankanywe ngasentla zifakwe kwi-shaft ephakathi kunye nesakhelo sokuqonda ukujikeleza okuqhubekayo kwe-tray yokuqokelela.

Ikhabhinethi yokulawula ixhotyiswe ngee-inverters, iinguqu zokulawula kunye nezinye izinto zokulawula isantya sokujikeleza kwediski yamagnetic nanini na.

Umazibuthe osisigxina kummandla wemagnethi uqulunqwe sisiqwenga esinye okanye iziqwenga ezininzi kwicala lobunzima, kwaye idiskhi yewebhu esisigxina ifakwe phakathi. Ummandla wemagnethi wamkela iiseti ezininzi zeepali zemagnethi ezineepolari ezichaseneyo ukuze zilungelelaniswe ngokutshintshanayo. Ngethuba lokujikeleza okuqhubekayo kwe-pan yokuqokelela, izinto zamagnetic zihlala ziwa kwi-pan yokuqokelela kunye namanzi okuhlamba kunye ne-desludge, ukwenzela ukuba izinto ezifunyenweyo zamagnetic zidibaniswe kunye neentsimbi eziqhelekileyo. Xa kuthelekiswa nomatshini wokuhlaziya, ukucoceka kuphezulu kwaye umphumo wokuhlaziya ungcono.

Indawo yemagnethi ebuthathaka iseti phakathi kwendawo kazibuthe kunye nendawo engeyiyo imagnetic kwidiski. Xa imathiriyeli yamagnetic ingena kwindawo engeyiyo imagnetic, ngenxa yobuthathaka bemagnethi yokutshintsha indawo kunye nendawo yokufunxa yemagnethi ebuthathaka iyancipha kancinci kancinci, isenzeko sokufuduka ngasemva kwesixhobo sombane siyancipha kakhulu. I-baffle ethambekele kwi-tray ye-material iphinda ithintele ukuhamba ngasemva kwezixhobo zemagneti kunye nokuvuza kwezinto, kwaye inokwenza ukuba izinto eziphathekayo zihambe ngokuthe ngcembe. Ngenxa yesenzo sobunzima kunye nokuhlamba kwamanzi, ukukhulula ngokukhawuleza kuyenzeka.

I-tray yokuqokelela ingumngxuma kunye nesakhiwo esitywinwe ngokupheleleyo, kwaye umphezulu we-adsorbing imathiriyeli yemagnethi yenziwe ngezinto ezingenamagnetic. Kwi-tray yokuqokelela, ipleyiti yesikhokelo ineembambo zangaphandle, ethambekele kwi-angle ethile kunye nokuphela kwendawo yokuqokelela. Injongo ephambili kukuthintela imagnethi. Ukuhamba ngasemva kwezinto kunye nokuvuza kwezinto. Ukuze kuncitshiswe idipozithi ye-ore slurry, ubuninzi beebhloko ezishukumisayo zokuvuselela i-ore slurry zicwangciswe malunga ne-pan yokuqokelela, kwaye kwangaxeshanye, ukukrazuka kwepleyiti yokuqokelela ngenxa yediphozithi ye-ore slurry nayo iyancitshiswa. .

Isicelo semveliso yoshishino

Uhlalutyo lwesiphumo sokubuyisela umatshini wokubuyisela umbindi webala le-semi-magnetic uzikhululayo

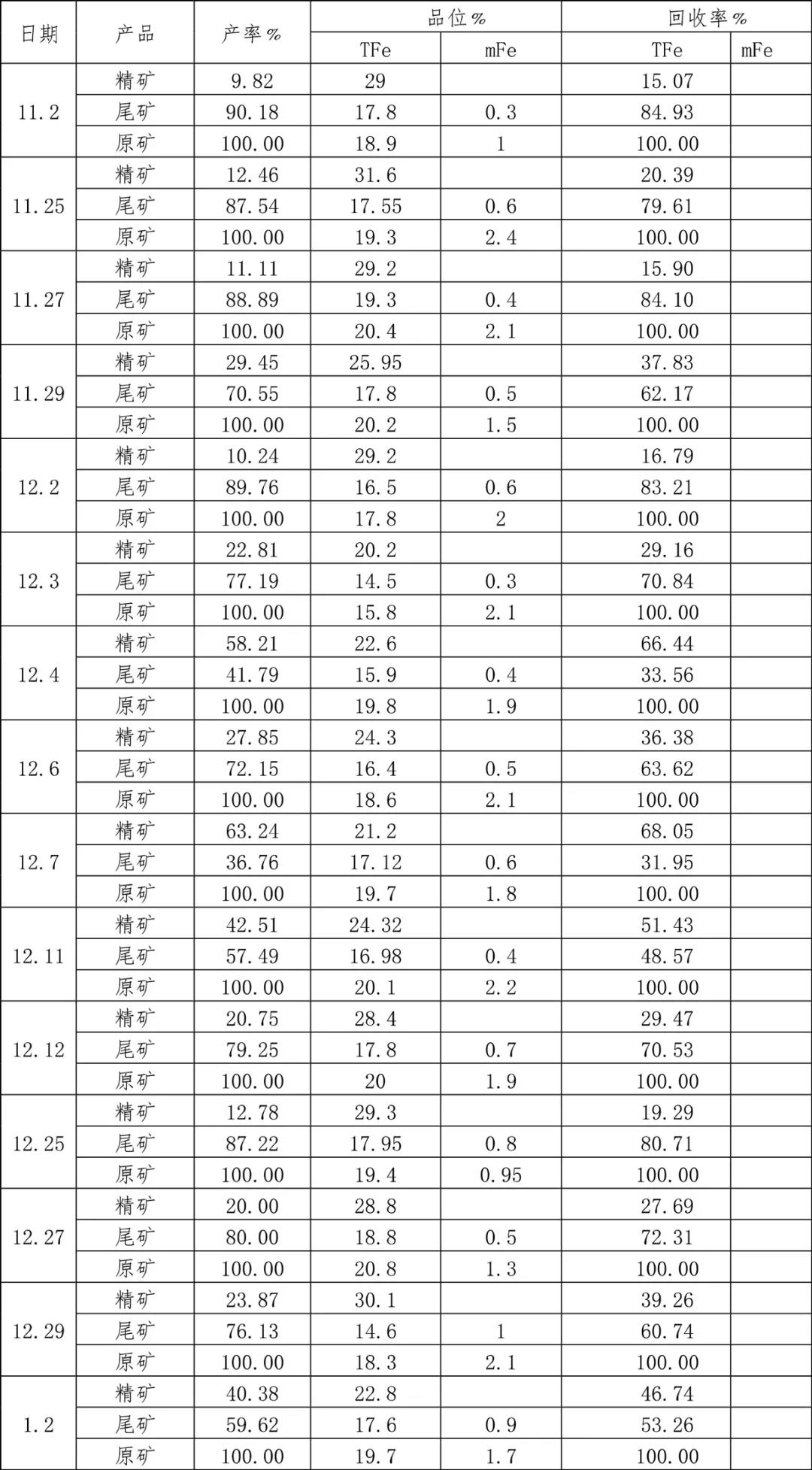

A medium-field amandla semi-magnetic self-uthula iitailings recovery machine kunye nomzekelo YCBW-15-8 esetyenziswa yinkampani yezemigodi ifakwe emva komatshini wokubuyisela ii-tailings owenziwe nge-ferrite kwinkqubo yemagnethi. Emva kwesiqingatha sonyaka sokusebenza, Isixhobo sisebenza ngokuqhelekileyo kwaye umphumo wokubuyisela ulungile. Emva kovavanyo oluninzi lwesampulu, iziphumo ziyanelisa. Iziphumo zovavanyo lwesampulu ezininzi zezi zilandelayo:

Ngohlalutyo lwedatha olungentla:

Umphumo wokubuyisela kwesi sixhobo: ibakala le-tailings liyancipha nge-2.16% emva kokuhlelwa, ibakala lentsimbi yamagnetic liyancipha nge-1.27% emva kokuhlelwa, kwaye ibakala eliphakathi kwe-ore eliphakathi liyi-26.53%. Umphumo wokubuyisela uyabonakala.

Amathuba emarike kunye neenzuzo zoqoqosho

Okwangoku, maninzi amashishini okwahlulwa kwemagnethi eTshayina, kwaye bambalwa kuwo abasebenzisa oomatshini bokubuyisela iintsalela zezimbiwa ze-ferrite, kodwa musa ukusebenzisa amandla aphakathi kwentsimi ye-semi-magnetic self-unloading tailings recovery machines. Ngoko ke, ithemba lemarike libanzi. Ukuba i-20% yamagnetic Iplanti yokucubungula ityalomali kule sixhobo, ibalwa ngokusekelwe kwiiyunithi ezingama-300 ngonyaka kunye nemodeli YCBW-15-8. Iyunithi nganye inokubuyisela i-7t/h yentsimbi ekrwada eyomileyo ngeyure, i-168t/h yentsimbi ekrwada eyomileyo ngosuku, kunye neentsuku ezingama-330 zomsebenzi ngonyaka, ukuchacha okupheleleyo kwe-55.44 yezigidi zeetoni, kunye ne-16.632 yezigidi zeetoni ziphinde zarisayikilishwa ngeeyunithi ezingama-300. Iinzuzo zoqoqosho zininzi, kwaye ukusetyenziswa kwesi sixhobo kunokunciphisa inkcitho yobutyebi bezimbiwa elizweni rhoqo ngonyaka.

Okwangoku, inqanaba leentsimbi zentsimbi ekrwada kwilizwe lam liphezulu ngokubanzi emva kokuhlelwa, nto leyo ebangela inkcitho eninzi yemithombo. Imithombo yezimbiwa isisiseko sokuphila nophuhliso lwabantu. Ngaphezulu kwe-95% yamandla kunye ne-80% yemathiriyeli ekrwada kwimizi-mveliso kwilizwe lam aphuma kwimigodi. Ngokukhula ngokukhawuleza koqoqosho lwelizwe lam, imfuno yemithombo yezimbiwa iyaqhubeka ukwanda. Kwelinye icala, ubutyebi bezimbiwa belizwe lam bujongene noxinzelelo olumandla lokunqongophala. Imithombo yezimbiwa ekudidi oluphezulu, ekulula ukuyihlela iyehla, kwaye izibonelelo zezimbiwa ezikumgangatho ophantsi, ekunzima ukuzihlela ziya zixatyiswa. Uphuhliso nophando koomatshini bokubuyisela iintsalela zeentsalela zezimbiwa ngaphezulu kwe-300mT kunempembelelo entle ekunciphiseni inkunkuma yesizwe kunye nokunyusa izinga lokusetyenziswa kwezimbiwa. Ukususela kumbono wophuhliso kunye nemiphumo yesicelo, iphucule ngokufanelekileyo izinga lokubuyisela i-ore magnetic. Ihlangabezana neemfuno zoyilo kwaye iyimveliso efanele ukukhuthazwa kunye nokusetyenziswa.

Ixesha lokuposa: May-12-2021