Kwinkqubo yokwahlulwa kwemagnethi yemagnethi, ngenxa yeagglomeration yamagnetic, kulula ukuvelisa "i-magnetic inclusions" kunye "ne-non-magnetic inclusions", echaphazela kakhulu ibakala lokugxila. IWalt sisizukulwana esitsha sezixhobo zokwahlula imagnethi ebuthathaka. Iqwalasela ngokubanzi imimandla yamandla ebanzi njengamandla kazibuthe, ubunzima, i-buoyancy, i-centrifugal force, njl. Ngokudibeneyo, iiparamitha zokusebenza zihlengahlengiswa ngokuzenzekelayo ngokweempawu ze-ore, ezinokunciphisa ngokufanelekileyo umxholo wokungcola okufana ne-silicon, i-phosphorus. , kunye nesulfure kwi-ores magnetic, kwaye ufumane i-high-grade magnetite concentrates kunye neemveliso eziphakathi ezifana nezigxininisi kwinkqubo yokwahlula magnetic, ezifanelekile kwangaphambili. Ugxininiso lokugqibela lulungele ukusebenza kwenzuzo ye-magnetite concentrator, evula indlela entsha yogxininiso lwentsimbi yelizwe lam ukuphumeza isicwangciso-qhinga “sokuphucula nokunciphisa ukungcola”.

Umgaqo wokusebenza

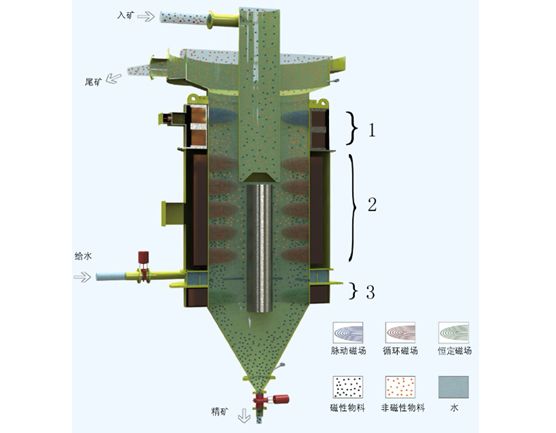

Intsimbi ekrwada ixhelelwa embindini nangaphezulu kumatshini we-elutriation ngentsimbi yokutyisa intsimbi kunye nombhobho wokutyisa intsimbi, kwaye ikhukuliswe ngamanzi agungxulwayo. Phakathi kweekhoyili ezimbini kunye naxa ikhoyili icinyiwe, ekubeni amandla ombane asezantsi abuthathaka kakhulu, achetywe kwaye asasazwe yisantya esiphezulu sokujikeleza kwamanzi okuhamba kwamanzi, ukuze i-ganggue enye, i-ore slime kunye nezinto ezidibeneyo ezixutywe kuyo. , ingakumbi amahlwempu ahlangeneyo. Ibhanti elibalekayo liphezulu, kwaye phantsi kwesenzo sokuhamba kwamanzi okujikelezayo okuthe gqolo ukuya phezulu, liyenyuka liye kutsho kumphetho ophuphumayo kwaye likhutshiwe ukuba libe ziintsila eziqulunqwe yimizimba edibeneyo.

Umgaqo osebenzayo womatshini wokukhetha i-electromagnetic panning

Iiminerali zemagnethi ezikwintsimbi ekrwada zenziwe nguzibuthe ngumhlaba wemagnethi oveliswa yikhoyili yombane, kwaye amasuntswana orentshi wemagnethi asebenze abe yimagnethi, kwaye uninzi lwemagnethi lutsalelana ukwenza amatyathanga omagnetic. unxibelelwano lokucinywa kombane luchithwa ngokupheleleyo ngokuchetywa kwe-axial phantsi kwesenzo sokujikeleza kwesantya esiphezulu kunye nokunyuka kwamanzi. Le nkqubo iqhutyelwa ngamaxesha amaninzi, ukwenzela ukuba izinto eziphathekayo zikwazi ukukhethwa ngamaxesha amaninzi kumatshini we-elutriation ukufumana i-high-grade magnetite concentrate, kwaye kwangaxeshanye, umxholo wokungcola okufana ne-SiO2 nayo iyancitshiswa.

Inkqubo yokulawula umatshini wokuhlamba

Umatshini we-elutriation uthatha ulawulo lwe-impulse-impulse, oko kukuthi, ukugxininiswa kokugqithiswa kunye nokugxininiswa kokuhamba ngaphantsi kweethagethi zolawulo.Uxinzelelo olugqithisiweyo lulawulwa ngubukhulu bamandla amagnetic field, kwaye ugxininiso oluphantsi lulawulwa ngokuvulwa kwezantsi. I-valve.Kwinkqubo yokulawula, ngokumisela amaxabiso ekujoliswe kuwo oxinaniso lokuphuphumayo kunye noxinzelelo olungaphantsi, inkqubo yokulawula ithatha i-algorithm yokulawula ehlakaniphile ukulawula amandla ombane kunye nokuvulwa kwevalve ephantsi ukugcina ixabiso ekujoliswe kulo phakathi koluhlu oluthile lokusebenza. .

Xa isixa sokutya kwe-ore singazinzanga, inkqubo yokulawula iya kulungelelanisa ngokuzenzekelayo ivalve esezantsi ngokotshintsho lwengxinano ye-underflow ngaphakathi kumatshini we-elutriation, ukuze i-magnetic medium ngaphakathi kumatshini we-elutriation ihlale ingatshintshi kwaye igcine indawo ezinzileyo yokuhlela; ukubonelelwa kwamanzi akuqinisekanga, inkqubo yokulawula ilungisa ubuninzi bomhlaba wamagnetic ngokwenguqu yokuxinwa kokugqithiswa komatshini wokuhlamba ukuqinisekisa ukuzinza kwesalathisi sokugxila.

Umatshini ozenzekelayo we-electromagnetic panning kunye nomatshini wokukhetha wamkela iPID-automatic yokulawula indlela yokuphucula, engadingi msebenzi wezandla kwaye ihlala isebenza kweyona ndawo ilungileyo. Ukusebenzisa i-Intanethi yeTekhnoloji yeZinto, iiparamitha ezisebenzayo zithunyelwa kwiqonga lelifu elikude, kunye ne-elektroniki. iifayile zisekwe kwisixhobo sokulawula umjikelezo wobomi bonke;Iingcali zenkampani yethu yokucubungula izimbiwa zinokuhlengahlengisa ukude iiparamitha zokulungisa izimbiwa zomatshini wokuhlamba ngeqonga lokubeka iliso elikude ukuze bakhonze abasebenzisi kangcono.

Imeko yokusetyenziswa komatshini wokukhetha i-electromagnetic panning

Ixesha lokuposa: Mar-21-2022