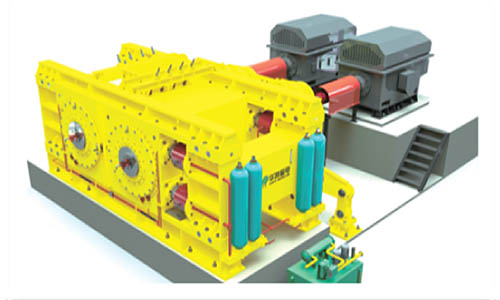

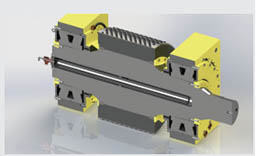

HPGM Series High Pressure Grinding Roll

Izinto eziluncedo kwiMveliso:

1. Uyilo loxinzelelo rhoqo luqinisekisa uxinzelelo olugudileyo phakathi kwemiqulu kwaye luqinisekisa umphumo wokutyumza.

2. Ukulungiswa kokuphambuka ngokuzenzekelayo, kunokukhawuleza ukulungelelanisa i-gap roll ukuze kuqinisekiswe ukugudiswa kwezixhobo.

3. Inkqubo yokuhlukana komda inciphisa umphumo weempembelelo ezinqamlekileyo kwimpembelelo yokutyumza.

4. Ngezikhonkwane ze-carbide ze-cemented, ubomi benkonzo ende, ukugcinwa lula, kunye nokutshintshwa.

5. Ibhanki yevalvu ithatha amacandelo angaphandle, kwaye inkqubo ye-hydraulic inoyilo olufanelekileyo kunye nokuthembeka okulungileyo.

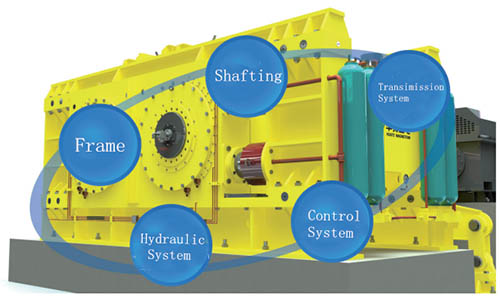

Iimpawu zesakhiwo seHPGR:

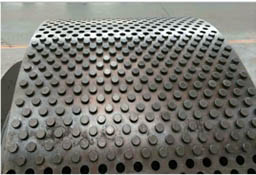

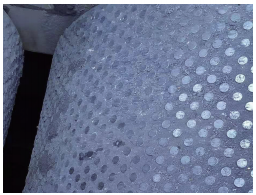

1. Uhlobo olutsha lweteknoloji ye-stud roll surface

Yamkela i-alloy studs ezikumgangatho ophezulu ezinobunzima obuphezulu kunye nokumelana nokunxiba kakuhle. Ilungiselelo le-stud liyilwe ngokulinganisa ikhompyutheni, kwaye ukulungelelaniswa kunengqiqo, enokuthi yenze i-uniform material layer phakathi kwe-studs, ikhusele ngokufanelekileyo i-studs kunye ne-roll surfaces, kunye nokuphucula ubomi benkonzo yokuguqa. I-studs ifakwe kunye ne-adhesives ekhethekileyo evela kumazwe angaphandle ukuze kube lula ukutshintshwa.

Impahla engekasilwa

Umphezulu oPhezulu wokuNxitywa oNganyanzeliyo uMphezulu onezikhonkwane

Emva kokuba izinto zikhutshiwe, i-dense material layer yenziwa kwi-roll surface ukukhusela i-roll surface.

Ikhekhe leMathiriyeli

Itekhnoloji yokwahlulahlula i-roll bushing kunye ne-main shaft

Umzimba oyintloko we-squeezing roll wenziwe ngetsimbi ekhandiweyo ephezulu, kwaye i-roll bushing yenziwe ngentsimbi ye-alloy ephezulu. I-shaft ephambili kunye nemiqulu yenziwe ngezinto ezahlukeneyo, eziphucula ukuqina kwe-shaft ephambili kunye nokuqina kwe-roll bushing. Ubomi benkonzo ye-shaft bushing buphuculwe kakhulu. Ukutshintshwa kwe-roll bushing kukulungele.

Ithwele itekhnoloji yokunyuka ngokukhawuleza kunye nokuhla

Umgangatho ophezulu weebheringi ze-tapered hole zamkelwe kwaye itanki yeoli yoxinzelelo oluphezulu yenziwe kwangaphambili. Ukuthwala kunokuchithwa ngokulula ngempompo yeoli yoxinzelelo oluphezulu, ukunciphisa kakhulu ubunzima bokutshintsha indawo yokuthwala kunye nokuphucula ukusebenza kakuhle kokugcinwa.

Itekhnoloji yokutywina edibeneyo emininzi

Isitywina sokutywinwa samkela iintlobo ezahlukeneyo ze-J kunye nohlobo lwe-V kunye ne-labyrinth seals, kwaye iteknoloji yokutywina edibeneyo iqinisekisa ngokufanelekileyo umphumo wokutywinwa kokuthwala.

Isakhelo samandla aphezulu

Isakhelo sidityaniswe ngentsimbi ekumgangatho ophezulu wekhabhoni. Amandla esakhelo onke ajongwe macala amathathu, anamandla aphezulu kunye nokuthembeka okuhle. Isakhelo sicutshungulwa nge-annealing edibeneyo kwaye i-deformation deformation incinci.

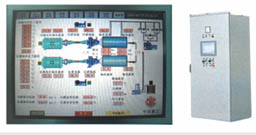

Umgangatho ophezulu kunye nenkqubo ethembekileyo ye-hydraulic

Ngokweempawu ezityumkileyo zezixhobo ezahlukeneyo, iiparitha zoxinzelelo lwenkqubo ye-hydraulic ziphuculwe, kwaye idizayini ekhethekileyo yamkelwa ngokukodwa kwiimpawu ezityumkileyo zamaminerali esinyithi njengentsimbi yentsimbi kunye ne-manganese ore. Iqela levalvu yehydraulic lithatha iimveliso zohlobo oludumileyo oluphuma kumazwe angaphandle kwaye lithembekile kwaye lizinzile.

Inkqubo yolawulo oluzenzekelayo kunye nenkqubo yokuthambisa ephakathi

Nge-Siemens PLC kunye neskrini esipheleleyo sokuthintela, kunye neskimu solawulo jikelele, umatshini wonke unokungahoywa, kwaye uxinzelelo kunye neeparitha ezahlukeneyo zinokuguqulwa ngokulula ukuququzelela ukutyunyuzwa kwamaminerali ahlukeneyo. Umatshini wonke wamkela inkqubo yokuthambisa esembindini, enokuthi ilungelelanise isixa sokuthambisa kunye nobuninzi beemeko zokusebenza.

Iimeko zeProjekthi ye-HPGR: